The Truth About Rack Collapses – Who Is Liable?

The Forklift Operator? Or the Rack Supplier? Or the Business Owner?

Recent news, as seen on TV and internet portals (link below), depicts a devastating rack collapse in Russia.

Link to Russian rack collapse video

The comments attached to the news bulletins, blogs and alike are pointed directly, and ONLY, at the “Forklift Operator”. Should they be?

When I see this kind of incident and hear the forklift driver copping ALL the blame, I want to shout out aloud — “Wake up guys!”. The forklift operator may well have contributed to this collapse. However, based on our view of the video, it was either a poorly designed rack structure, and/or its condition, which was more likely to be the major contributing cause of the collapse.

The Standards…

Pallet racking in Australia should meet the following three relevant standards…

- AS 4084—1993 “Steel Storage Racking”

- AS/NZS 4600:2005 “Cold Formed Steel Structures”

- FEM 10.2.01 “The Design of Static Steel Pallet Racking”

Users should also be aware of their own obligations for use of pallet racking. See…

-

- FEM 10.2.04 “Guidelines for the Safe Use of Static Steel Racking and Shelving, User’s Guide”

Note: Both the Colby and Dexion Rack Operation and Maintenance Manuals are based extensively on the above code.

Pallet racking, when properly designed, installed and maintained in accordance with “The Standards”, should not suffer total collapse as viewed in these scenes, although some localised damage may occur.

So, if this had happened in Australia, who would have been held responsible?

The truth is, all three of the above parties could be held liable for this workplace incident — The forklift operator and the rack supplier and the business owner.

Why…

“Due diligence is the effort made by an ordinarily prudent or responsible party to avoid harm to another party. Failure to make this effort may be considered negligence.

“In demonstrating due diligence, Directors and Managers have a clear responsibility to investigate and seek assurances on the suitability and adequacy of systems of work.”

— Australian Industry Group seminar on “Due Diligence” 28th October, 2009 – Brisbane

Bottom line is – those in charge are responsible for ensuring the racking structure is sound, is fit for purpose, meets the Standards, is installed correctly, is not overloaded, etc. etc. This responsibility is not conveniently shifted entirely and only to the guy who supplied the cheap racking, or the guy who you or your supplier contracted to install it, or the forklift driver.

Also see…

- “Relevant person’s obligations (s 29)” —Qld WHS Act 1995

- “Executive Officer’s Personal Liablility (s 167)” — Qld WHS Act 1995

- “Obligations to ensure WHS (s 23)” — Qld WHS Act 1995

Imagine for just one moment that there was someone standing in the aisle when that rack went down. Not a pleasant thought at all, is it?

Your 10 Point Safety Checklist

Here is a 10 point check list that will provide some essential protection against such a disastrous event…

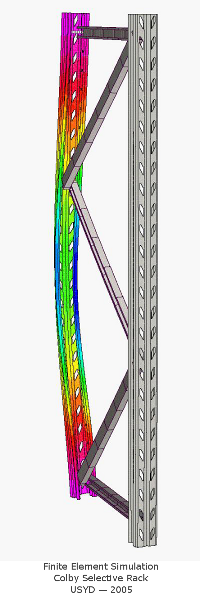

- Get your rack supplier to provide you with written proof that their offered structure will do the job. “Proof” is an engineer’s document displaying accurate information about YOUR entire rack installation, the loads YOU will be applying and the results of the stress that YOUR loads will have on the designed rack being offered. Be very wary of simple statements or certificates – verbal or written – simply stating “it will do the job” or “our brand meets the standards”. Keep in mind that rack components alone do not meet the Standards – only an INSTALLED SYSTEM, conforming to ALL of the requirements can meet the Standards.

- Check that your completed installation does actually conform with the rack supplier’s engineered design – especially if you are installing it yourself or using contractors to perform the installation. Note: Under the Queensland Building Services Authority Act 1991, an installation contractor requires a licence in Non-Structural Metal Fabrication and Installation (this includes installation of steel storage racking).

- Establish and maintain your rack maintenance and incident reporting system. Third party consultants such as AIG (Australian Industry Group) can provide assistance in developing an adequate SMS (Safety Management System). For more information from AIG, freecall: 1800 722 420.

- Never overload your racks – make periodic checks for overloading a part of your regular maintenance program. If you feel your rack may be overloaded but are unsure, get your supplier to check it for you. If you’re not confident of your supplier’s assessment, ask a third party to take a look – ensure to let your supplier know the results of the third party’s assessment.

- Have repairs performed by your supplier or their approved repairers ONLY.

- Have your rack inspected by your supplier or a supplier-recommended contractor who specialises in rack inspections. Check their processes and reporting structure to satisfy yourself that they are working in your best interests – be wary of anyone offering hand written reports or anyone that simply reports on necessary repairs.

- Never alter the racking in any way without checking with your supplier first. If alterations are approved, your supplier’s reply should include a fresh up-to-date engineer’s report as mentioned in item 1 above. Note: Simple relocation of beam levels can alter the rack’s stability.

- Ensure your racks are properly signed with the allowable loads, conforming to the supplier’s stated loads and the engineer’s certificate provided. If you don’t understand the load signs, have your supplier explain them to you.

- Never install substitute components – this is dangerous and will render all other measures of prevention invalid. “Substitute Components” would include aftermarket parts not made or approved for your system by the original manufacturer. (also see Counterfeit Rack

- Read your Rack Operation and Maintenance Manual (your supplier should have provided you with a copy).

If you are uneasy about your rack, your supplier or any of the above check points, call Inspect-a-RACK or a trustworthy third party to discuss your concerns.